Warehouse Solutions: How to Choose, Set Up, and Keep It Running Smoothly

If you’re hunting for a place to store inventory, ship orders, or manage returns, you need a warehouse solution that fits your business, not the other way around. The good news is you don’t have to build a massive complex to get good results. Small shops can use shared spaces, and larger brands can add smart tech to an existing building. Below you’ll get straight‑forward advice that works for any size operation.

Choosing the Right Warehouse Solution

First, figure out what you actually need. Do you need a short‑term spot for seasonal stock, or a permanent hub for daily shipments? If you only move a few pallets a month, a flexible‑lease warehouse or a third‑party logistics (3PL) partner can save you money on rent and utilities. For high‑volume sellers, a dedicated space lets you control layout, staffing, and inventory flow.

Look at location next. Being close to major highways, ports, or your biggest customers cuts fuel costs and delivery times. Use tools like the “Largest Amazon Warehouse” case study to see how proximity can speed up order fulfillment. Also, check zoning rules – some areas restrict heavy equipment or hazardous items.

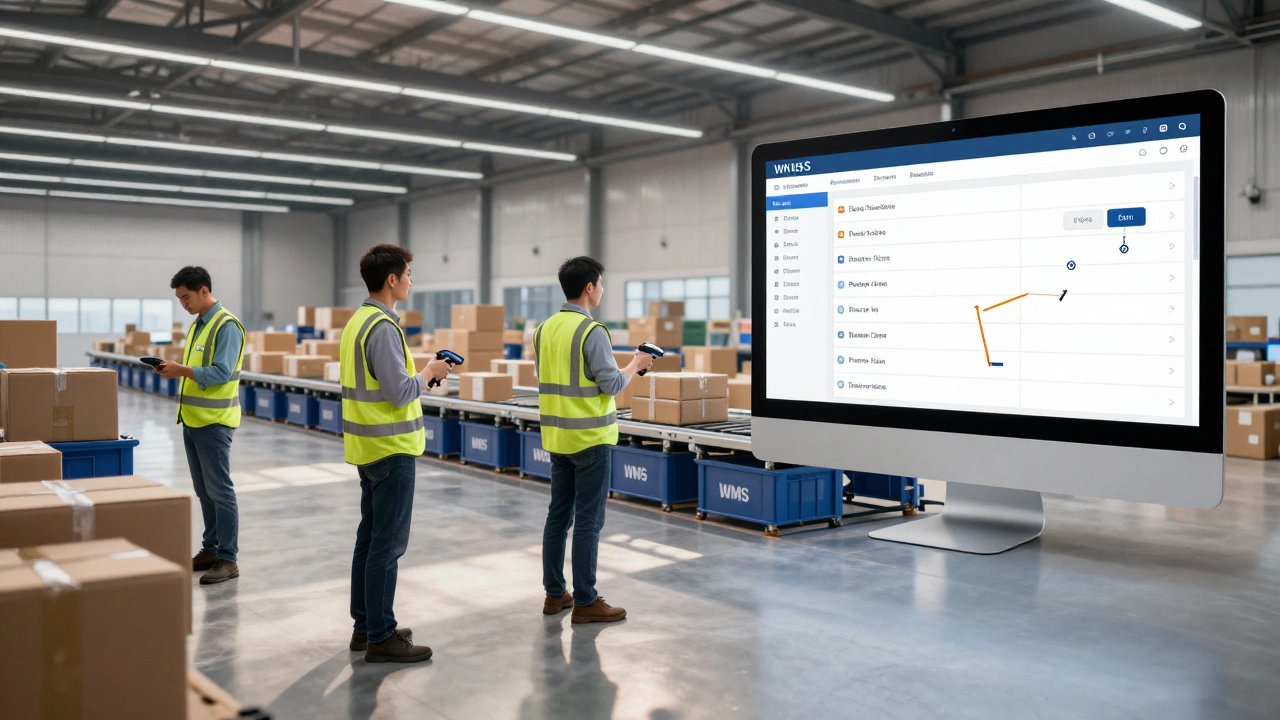

Technology is a game‑changer. Modern warehouse management software (WMS) can track every box, suggest optimal aisle placement, and even predict when you’ll run out of space. The "Top Supply Chain Management Software" guide lists a few 2025 favorites that integrate with e‑logistics platforms, so you can automate pick‑and‑pack tasks and reduce errors.

Tips to Keep Your Warehouse Running Smoothly

Once you’ve got the space, set up a clear flow: receiving area, storage zones, picking lanes, and shipping dock. Keep high‑turn items near the entrance and low‑turn stock toward the back. This reduces travel time for staff and speeds up order processing.

Invest in simple safety upgrades. Good lighting, anti‑slip flooring, and clearly marked aisles prevent accidents and keep productivity high. If you store heavy pallets, make sure your racking meets the load ratings you need – the last thing you want is a collapsed shelf.

Regularly review your costs. Compare carrier rates for overnight shipping, like the "Best Place for Overnight Shipping" guide, and negotiate better terms if you ship a lot. Small changes, like consolidating shipments or using a courier for fragile items, can shave off a hefty percentage of your logistics budget.

Finally, train your team on the tech you use. A quick walkthrough of the WMS dashboard can turn a confusing spreadsheet into a real‑time inventory pulse. When everyone knows where items live and how to move them, mistakes drop and morale rises.

Warehouse solutions are about matching the right space, tools, and processes to your business goals. Start small, test a few ideas, and scale up as demand grows. With the right mix of location, technology, and smart layout, you’ll turn your warehouse from a cost center into a growth engine.

WMS and ERP systems serve different roles in warehouse operations. Learn how WMS handles real-time inventory and picking, while ERP manages finance and sales - and why you need both to scale efficiently.

Jan, 15 2026

Learn what SAP stands for, explore its warehouse modules, compare WM vs. EWM, and get a step‑by‑step guide to implementing SAP in any distribution center.

Oct, 23 2025

Curious about what goes into each Coca-Cola bottle? This article breaks down the origins of Coca-Cola's key ingredients, from sugar to flavorings, and explains how they manage global sourcing efficiently. You'll find out where and how these raw materials are collected, plus some little-known facts about their supply chain. Learn why warehouse solutions play a big part in keeping production fast and reliable. By the end, you’ll see what it takes behind the scenes to get that familiar soda onto your shelf.

Apr, 28 2025

Ever wondered who owns the biggest warehouse in the world? This article dives into the intriguing world of gigantic warehouses. Learn not just about the colossal size, but also the logistics and operations that make them vital to global supply chains. Get insights into the owner’s strategies in managing such massive spaces and what makes these behemoths tick. Discover tips for efficient warehouse solutions that can be inspired by these industry giants.

Feb, 16 2025

Data centers are classified into four tiers, from Tier 1 to Tier 4, each offering different levels of redundancy, cooling, and connectivity to meet various business needs. Tier 1 represents the most basic level with limited redundancy, while Tier 4 offers the highest level of reliability and fault tolerance. Understanding these tiers is crucial for businesses to choose a data center that aligns with their operational expectations and budget requirements. This article explores the key characteristics and benefits of each tier, providing insights to help make informed decisions.

Dec, 31 2024